Research Article

Research Article

A Review on Geothermal Energy Pile Foundation, Its Construction, Design and Thermal Testing

Abdullah I Al-Mhaidib* and Kehinde Lemboye

Department of Civil Engineering, College of Engineering, King Saud University, Saudi Arabia

Abdullah I Al-Mhaidib, Department of Civil Engineering, College of Engineering, King Saud University, Saudi Arabia.

Received Date:November 28, 2022; Published Date: January 10, 2023

Abstract

Geothermal energy pile foundations are alternative means of harvesting eco-friendly thermal energy generated and stored in the Earth for heating and cooling purposes. Rapid growth in the utilization of geothermal structures over the years has led to several research efforts centered on understanding their thermal and thermo-mechanical performance through in-situ characterization. This paper discusses considerably, the review of literature on the background, construction, and design of geothermal energy piles, as well as the principle behind the technology. Furthermore, an overview of the key factors to be considered in the design such as the thermal conductivity, thermal diffusivity, and the specific heat capacity was presented. More importantly, under thermo-mechanical loading, the pile shaft capacity has been reported to increase when heated and upon cooling, a recovery of the initial capacity of the pile. Also, the thermal loads and displacements resulting from the geothermal use of the energy piles are not expected to contribute to geotechnical failure. Lastly, insight into the thermal response test, the theoretical background of thermal analysis, and a few previous field thermal response tests were presented. This paper has found that geothermal energy piles are one of the best candidates for sustainable energy, even though there are some limitations in the guidelines for design and testing for large schemes.

Keywords:Conductivity; Energy pile; Geothermal; Heat transfer; Pump; Sustainable; Thermal

Introduction

The depletion of fossil fuels, increasing demand for sustainable energy, and the emission of greenhouse gases have led to an inclined growth in the utilization of renewable energy (solar, wind, hydro, geothermal, biomass, etc.). Geothermal energy is an attractive renewable technology that may be extracted from different depths below the crust of the earth. Deep geothermal energy is obtained from the hot water/rock in the deeper portion of the earth’s crust whereas shallow geothermal energy is from heat available at shallow depths. Shallow geothermal energy provides sustainable baseload heating/cooling for buildings with the aid of a ground source heat pump (GSHP). The GSHP pumps heat from or to the earth using a heat exchanger placed within the earth at depths of 5 m or more below the ground surface level, where temperatures are relatively stable regardless of the outside ambient air temperature. In Austria and Switzerland, shallow geothermal energy has also been increasingly obtained from foundation elements since the beginning of the 1980s initially from base slabs, then from piles in 1984, and from diaphragm walls in 1996 [1]. Geothermal energy shows less variation in energy supply and requires less maintenance compared to other forms of renewable energy. Conventional ground source heat pumps (GSHPs) with vertical boreholes and energy foundations (pile, diaphragm/retaining walls, tunnels) have been employed over the years to extract geothermal energy from the ground [2]. Due to the good thermal properties (conductivity and conservation) of concrete, the heat transfer is significantly higher than in the case of vertical boreholes [3]. Energy foundation has shown to be a viable alternative to reduce the cost associated with drilling boreholes required for vertical GSHPs [4]. Studies also suggest that they can reduce the operational cost required for heating/cooling by 80% [5], and the emission of greenhouse gas by 66% or more compared to traditional methods of heating and cooling [6]. Their application has become popular in Europe and North America.

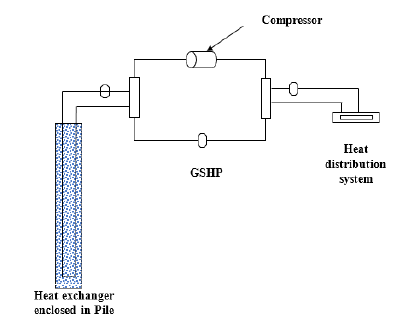

Geothermal energy piles also referred to as heat exchanger piles consist of pile foundations combined with closed-loop ground source heat pump systems. These loops are normally a series of High-Density Polyethylene (HDPE) tubular pipes (absorber pipes) that can transmit a fluid (often water) throughout the foundation [7]. Heat exchanger piles are cost-effective because they serve a dual purpose. Firstly, they serve a primary objective of transferring load from the structure beyond unfavorable layers to a firm bearing layer of soil or rock. Subsequently, they serve a secondary purpose in extracting shallow geothermal heat from the ground. With the aid of the fluid as the transfer medium, the substantial mass of the foundations and the ground, a heat reservoir for heating the building in winter, or a heat sink for cooling the building in summer can be achieved. Basically, the energy pile system consists of three main parts: (i) an earth connection via a heat exchanger enclosed in the pile foundation, (ii) a pump system, and (iii) a heat distribution system [6], as illustrated in Figure 1

Figure 1:Schematic illustration of the energy pile system Adapted from [6].

This paper provides a review of the background, construction, and design of geothermal energy piles as well as the factors governing the design, the principle behind the technology, the behavior under coupled thermo-mechanical loading, and the testing procedure. The study presented a few cases of thermal response testing carried out in the field.

Construction of Geothermal Energy Piles

Foundation piles whose primary function is for structural purposes are simultaneously used as heat exchangers by incorporating one or more loops of HDPE pipes over the length of the pile. The geometry of the pile (diameter and length) should be designed to resist the applied structural loads, and not increased to suit the geothermal requirements. However, the amount of thermal energy harvested cannot be guaranteed to satisfy the entire need of the building and should be designed as part of a hybrid heating and cooling system [8].

During the construction of the geothermal energy pile, the soil is initially bored out similarly to the typical pile foundation. Thereafter, a rigid, welded reinforcement cage is inserted. HDPE plastic pipes with a diameter of 20 or 25 mm, with a wall thickness of 2·00 or 2·30 mm respectively, are fixed to the reinforcement cages of the pile foundation (Figure 2) and are positioned to form multiple individuals closed loops that circulate either water, water with 20-25% antifreeze like Mono Ethylene Glycol or a saline solution through a heat carrier fluid. Other materials used for the heat carrier fluid pipes include steel, and copper [9]. Typically loops of eight vertical runs would be provided in a 600 mm diameter pile [10]. The configuration of the HDPE pipes varies, including U pipes, UU pipes, or W pipes. The loops are fitted with a locking valve and manometer at the top of the pile cage. Before concreting, an integrity test is conducted by pressurizing the HDPE pipes to around 8 bar and resisting the head of the wet concrete without collapsing [1].

After concreting operation, the pressure is maintained until the concrete hardens and reapplied before the pipes are finally enclosed. The protruding pipes at the tops of the cage are held back to avoid damage and a tremie pipe is placed at the base of the pile. Concrete is poured through the tremie, and it is raised as the concrete fills the pile. After the construction of the pile, the HDPE pipes are connected to a heat exchanger (GSHP) which is then con nected to a secondary circuit of pipes in the floors and walls of the building [10]. The geothermal effectiveness of piles less than 300 mm in diameter is much reduced due to lower surface area and the limited number of loops that can be fitted; the economically minimum depth of an energy pile is about 6 m [10] According to [1], for continuous flight auger (CFA) piling, the final integrity of the HDPE pipes may be affected by the plunging of the heat exchanger with the reinforcement cage into fresh pile concrete. This setback can be overcome by providing a stiff pile reinforcement cage achieved by welding the helical reinforcement to the vertical reinforcement bars. Simply connecting with wires would cause the reinforcement cage to become overly deformed during lifting and insertion into the concrete pile. Consequently, for energy piles, the rotary boring technique should be preferred, and a relatively rigid reinforcement cage is recommended even in this case.

Figure 2:HDPE pipes attached to pile reinforcement [34].

Principles of Geothermal Utilization for Energy Pile System

Geothermal heat exchanger technology is the most effective method for space heating or cooling purposes [11,12]. The principle of the energy pile system is to transfer heat to and from the earth and the heat pump system through heat exchanger HDPE pipes placed within the pile. Studies have shown that the ground temperature below a certain depth remains relatively constant at around 10 - 15 ℃ (and in the tropics as high as 20 - 25℃) throughout the year [1]. For example, the variation in temperature with depth measured at different locations is presented in Table 1.

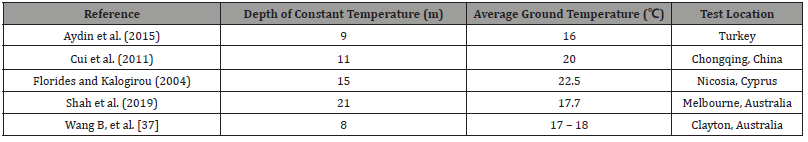

Table 1:Relative ground temperature measured at different locations.

During winter (heating cycle), the ground temperature is usually higher than the atmospheric air, this natural heat is collected through the loops and carried by heat transfer fluid to the GSHP in the building. Thus, been considered a heat source. The GSHP uses electrically driven compressors and heat exchangers to concentrate the heat from the ground and release it inside the building at a higher temperature via the heating, ventilation, and air conditioning (HVAC) unit. In contrast, during the summer period (cooling cycle) the whole process takes place in a reversed fashion. In this scenario, excessive heat is extracted from the building and transferred to the heat transfer fluid with the aid of the GSHP unit. The heat then travels along the loop and is subsequently absorbed by the ground, being used as a heat sink for injecting heat.

Design of geothermal energy pile

In the United Kingdom, a standard has been proposed Ground Source Heat Pump Association [13], to guide the geotechnical and structural design of energy piles. In general, two major factors need to be considered in any design procedure: (i) the in-service behavior and (ii) the failure scenario. The primary function of the energy pile regardless of its role in geothermal energy extraction is to safely transmit the loads without unacceptable settlement or damage to the superstructure or neighboring structures. While incorporating an additional type of load (thermal) to the pile, the design has been suggested to follow the same procedure as that of a traditional pile. The major goal in the design of an energy pile is to quantify the thermal load and apply afterward the factor of safety used in the traditional pile design [13]. However, for safety purposes, a high conservative factor of safety is usually employed in the traditional pile design procedure which in turn leads to more cost during construction. The thermal loads on pile can be considered variable static loads and the temperature change as well can be defined with respect to the temperature inputs involved in the building energy design, the associated thermal power for heating and cooling, the operation time, and the thermal properties of the concrete and that of the ground [14]. The thermal demand to be satisfied by a geothermal energy system can be estimated following standard procedures recommended by either [15]. Handbook of Fundamentals or ACCA [16] according to [17].

Knellwolf C, et al. [18] introduced a one-dimensional finite

difference method for designing geothermal energy piles that assess

the main effects of temperature changes on pile behavior. The

model was formulated according to the load transfer approach by

[19,20]. The design method by [18] was based on the following simplifications:

• Consideration is given only to the axial displacements.

• The Young’s modulus, Epile, and coefficient of thermal expansion,

α, of the pile remain constant along the pile and do not

change with temperature.

• The relationships between the shaft friction/shaft displacement,

head stress/head displacement, and base stress/base

displacement are known.

• The soil and soil-pile interaction properties do not change with

temperature.

The load transfer functions proposed by [21] based on the Menard pressure meter modulus value were adopted. The thermal load was added to the load-displacement model by using the null point theory proposed by [22] for the energy piles. The null point along the pile length is regarded as no movement point during thermal loading. Thus, the movement of the pile was evaluated from the null point along the length of the pile.

Governing Factors in Energy Pile Design

The thermal properties of the soil are an important governing factor for the design of geothermal energy foundations and borehole heat exchange systems. The required number of heat exchangers depends on the thermal properties of the soil. The most paramount thermal properties of the soil are: (i) the thermal conductivity (𝜆), (ii) specific heat capacity (c), and (iii) thermal diffusivity (α). These properties depend on soil types, composition, water content, density, and soil constituents (mineralogical content).

Thermal conductivity (𝜆)/

Soil thermal conductivity measurements describe the soil properties

which govern the flow of heat through the soil. It is described

as the quantity of heat passing through a unit area in a unit of time

under a unit temperature gradient. The ability of a material to

conduct heat depends on the soil particles, porosity, and moisture

content. The thermal conductivity of soil is significantly influenced

by the water content, texture, mineralogical composition, and bulk

density [23]. Thus, an increase in either the saturation or 2017dry

density of the soil will yield an increase in its thermal conductivity

[24]. Studies have shown that the thermal conductivity of soil

increases remarkably with increasing groundwater levels or the

presence of moisture [25,26]. It can be estimated from empirical

formulas, laboratory tests, and field tests. Measurements in the

laboratory are quicker and cheaper but certain conditions such as

the presence of groundwater flow, spatial heterogeneity, and scale

effects directly impact the thermal properties [27]. The most commonly

used standards for measurement of soil thermal conductivity

are:

• ASTM D5334-14 Standard Test Method for Determination of

Thermal Conductivity of Soil and Soft Rock by Thermal Needle

Probe Procedure [28].

• IEEE Std 442-1981 (Reaffirmed 2003), IEEE Guide for Soil

Thermal Resistivity Measurements [29].

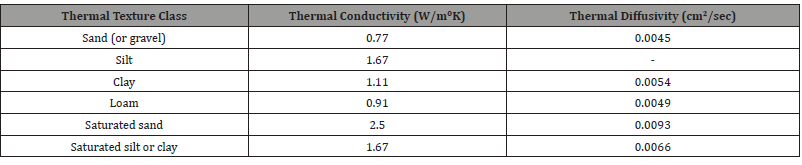

Both methods rely on thermal needles and can be conducted in the field or the laboratory by simply inserting the needles into the soil. However, the most accurate method is to construct a borehole and utilize it to determine soil thermal conductivity [30]. Typical soil thermal conductivity values are presented in Table 2.

Thermal diffusivity (α)

Soil thermal diffusivity is the parameter that describes the rate of transmission of temperature change within the soil. Simply put, it is the property that determines how easily and rapidly the temperature of the soil can change. Typical soil thermal diffusivity values are presented in Table 2.

Table 2:mal properties of soil [31].

Specific heat capacity (c)

The specific heat capacity of soil solids represents the amount of heat required to raise the temperature by one degree for a unit of mass of dry soil particles [32]. It is a useful parameter for characterizing the amount of heat that can be stored in the soil. It characterizes the quantity of heat that can be added to or removed from the soil per unit change in temperature. It can be determined by adding the heat capacities of different constituents of the soil as per volume and is measured in J/kgK. Also, it depends on porosity, mineral content, organic content, air, etc. The thermal capacity of the soil increases with an increase in water content but decreases in case of freezing [1].

Heat Transfer in Soil and Concrete

There are three essentially different processes through which heat can be transported in soil: conduction, convection, and radiation [33]. Heat conduction is a process whereby heat is transferred from one region of the medium to another, without visible motion in the medium. The heat energy is passed from molecule to molecule. The transport of heat by fluid in motion is called convection. Heat convection with accompanying phase changes can increase heat transfer tremendously. This is especially true for water, which has very high values of latent heat of condensation/evaporation and freezing/melting. Radiation is the transfer of thermal energy from a body to its surroundings by electromagnetic waves. Conduction is the dominant way of heat flowing in the soil while convection and radiation are less dominant. However, if there is a high flow rate of groundwater in the soil, convection also becomes the dominant means of heat flow [34].

The difference in temperature between the ground, the pile, and the heat carrier fluid passing through the HDPE pipes, generates the heat transfer in the geothermal system. The principle involved in this process is convective heat flow between the heat carrier fluid and HDPE pipe, conductive heat flow in the pipe’s wall, conductive heat flow in the concrete pile, conductive heat flow in the soil, and convective heat flow in the soil if the groundwater flow speed is higher than 0.5-1.0 m/day [14]. Heat transfer in the concrete is governed by three thermal properties: thermal conductivity, specific heat capacity, and thermal diffusivity. Concrete has good thermal conductivity and thermal storage capacity, which makes it an ideal material for extracting geothermal energy. The specific heat capacity of concrete is greatly influenced by the type of aggregate, moisture content, and density. The thermal conductivity of concrete ranges from 1.4 to 3.6 W/mK and varies with the density and permeability of concrete [35]. When specific details information about the aggregate proportion in the pile concrete and their properties, and types are not known; the pile thermal conductivity should not be assumed more than 1.5 W/mK [13]. For large diameter piles equipped with heat transfer pipes located in the center, the concrete is suggested to play a considerably more significant role in the process of heat transfer relative to the ground [36].

Pile Behavior Under Thermal Loading

[22] assessed the possibility of any significant impact of cyclic heating and cooling on the performance of the energy pile. When a pile is heated or cooled, it tends to expand or contract about a null point. Thus, during the extraction of heat (winter/heating cycle) pile contracts, and during injection of the heat (summer/cooling cycle) pile expands.

According to [22], it is assumed that

• The pile load will be resisted on the shaft alone, and the resistance

generated is uniform along the length of the shaft i.e.,

constant rate of change in strain with depth.

• The applied temperature changes are uniform over the length

of the pile and therefore the pile expands/contracts about a

‘null’ point at mid-depth.

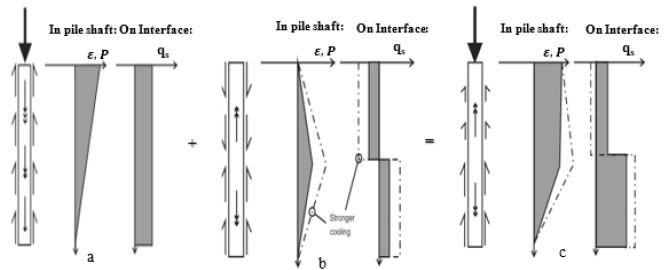

Figure 3:Mechanisms for response of pile to thermal loading (a) load only; (b) cooling only; (c) combined load and cooling.

Under compressive loading alone, the pile moves into the supporting soil, and resistance at the pile/soil interface opposes the loading as shown in Figure 3a. The mobilized shaft resistance is constant and as a result, the strain (ԑ) and load (P) reduce linearly with depth. During the cooling cycle, if both ends of the pile are unrestrained from moving, the pile contracts, and any restrain offered to the pile shaft will therefore lead to tensile strain/load developing (Figure 3b). Along the upper part of the shaft, shear stress (qs) on the pile/soil interface will be mobilized in the same direction as that mobilized by compression loading applied at the pile head, while shear stress will be in the opposite direction in the lower part of the pile. The axial loads become less compressive and can become tensile during a cooling cycle in combination with a compressive load at the pile head, while the mobilized shaft resistance rises in the upper part of the pile and decreases in the lower part (Figure 3c).

However, during the heating cycle, the pile expands, and any restraint offered to the pile shaft will therefore lead to compressive strain/load developing (Figure 4a). At the pile/soil interface, the reverse effect of the cooling cycle will develop. The axial load may become more compressive when during the heating cycle under a compressive head load, with the mobilized shaft resistance decreasing in the upper half of the pile and increasing in the lower half (Figure 4b). According to [37], it was observed that while the pile was heated, there was an increase in the pile shaft capacity and upon cooling, the initial capacity of the pile was recovered.

Figure 4:Mechanisms for response of pile to thermal loading (a) load only; (b) heating only; (c) combined load and heating.

PJ Bourne-Webb, et al. [22] reported further that, depending on the magnitude of the temperature change (and the degree of pile axial fixity), there is the potential for tensile axial forces to develop during cooling, and for a significant increase in axial force to develop during heating.

Studies have however suggested that the thermal loads and displacements resulting from the geothermal use of the energy piles are not likely to lead to geotechnical failure. Mimouni T, et al. [38] demonstrated that under monotonic thermal loading the null point will always move towards the pile end to maintain the equilibrium, even if the ultimate bearing force (friction and base) is mobilized. This can be attributed to the fact that the null point will prevent excessive settlement/heave since at least this point remains stable under temperature variations, ensuring equilibrium concerning a collapse mechanism. However, [39] reported that thermal loads cause negligible effects at ultimate limit states from both a geotechnical and a structural perspective, while they cause significant effects that should be considered at serviceability limit states. Bao X, et al. [40] proposed that the unequal strain that develops in a pile should be considered for its long-term application and more attention should be centered on the long-term unrecoverable displacement of the energy pile resulting from the thermal plastic strain and thermal soil consolidation.

Thermal Response Test (TRT)

To achieve optimal geothermal energy, the design of geothermal systems requires the knowledge of the thermal characteristics of both the GHE and the ground surrounding them. There are two key design parameters: (i) the GHE thermal resistance, R (K m/W), and (ii) the ground thermal conductivity, λg (W/m/K). Thus, the most reliable way to obtain this information is via an in-situ technique known as thermal response testing (TRT) [41,42]. In the case of small schemes, it might not be economical to perform a test compared to the adoption of conservative thermal properties during the design process. However, for larger schemes, or in cases where there is a doubt about in situ thermal properties, the [13] recommended that a thermal response test is required to be conducted. The test is conducted by injecting the heat into the ground via heat exchanger fluid at a constant rate and the corresponding inlet and outlet temperature of the fluid shall be determined during the test [43]. This technique was first proposed by [42] for borehole heat exchangers at an international conference in Stockholm.

The GSHP [13] has published a guideline for conducting the

TRT test in the geothermal piles which recommend that:

• If the potential for use of thermal piles has been identified,

then a site investigation borehole may be equipped with a single

U-tube and used to carry out a TRT.

• If the diameter of the thermal piles is less than or equal to

300mm then a TRT test may be carried out using the pile, following

the same procedure as for a borehole heat exchanger.

• If the diameter of the thermal piles is greater than 300mm

then the TRT is likely to be of greater duration than the borehole

test and the data obtained requires a more sophisticated

interpretation technique.

• To determine the stress-strain behavior of a pile during heating

and cooling the pile load test could be extended to include

both heat injection and heat rejection to the pile while it is

maintained under load. Monitoring of the temperatures and

strain developed within the pile itself then allows assessment

of the stress-strain response of the pile as well as its thermal

characteristics.

Theoretical background of thermal analysis

During the TRT, heat is injected into the GHE at a constant rate, Q (W), and the change of temperature of the heat transfer fluid, Tf (℃) is monitored for two or three days. The temperature in the borehole or of the pile, Tr(t) (℃), with time, t (sec), can be expressed by the following analytical equation [44]:

Where T0 is the undisturbed ground temperature, Q is the applied heat transfer rate in W, λg is the ground thermal conductivity, H is the GHE length in m, αg is the thermal diffusivity in m2/s, rb is the GHE radius in m, and γ is Euler’s constant (0.5772). The rate of change in the heat transfer fluid temperature is given by:

Where Rb is the pile resistance (mK/W),

Knowing the power input required to heat the fluid, the effective thermal conductivity of the soil can be determined from the analysis of the rate of change in temperature with time. There is a linear relationship between the heat carrier fluid temperature, Tf and the log of time which can be expressed as:

Thus, we have

The thermal conductivity can be evaluated from the gradient, m of the temperature versus ln(time) graph [46].

The GHE thermal resistance Rb can also be determined from the straight-line intercept in the same temperature versus ln(time) graph.

In common practice, 2 0 / 5 g b α t γ = F = is taken as the minimum time for the application of Equation (2) [45], where F0 is the Fourier number. The implementation of this restriction also ensures that the GHE is in a thermal steady state, an additional constraint required to ensure that the value of Rb is constant [47]. This minimum time criteria when applied to a borehole GHE typically equates to less than ten hours [48]. However, when the restriction is applied to larger diameter energy piles the minimum time becomes several days or even weeks [49], having significant implications for TRT durations and, hence, cost. As a consequence, however, theoretical studies have shown that there are limitations to applying routine TRT methods to piles due to their larger diameter [36], and the guidelines proposed by the [13] have limited application to small diameter piles not more than 300 mm. Extending the duration of the TRT in the case of large diameter piles as specified by the [13] has been considered to be uneconomical in most cases according to [36]. Thus, an alternative would be to test a borehole having a similar depth to the proposed piles during the ground investigation stage of a project. In addition, field studies [50,51] have shown that where a line source method is used in interpreting the data from the TRT, there is a potential for systematic overestimation of the thermal conductivity.

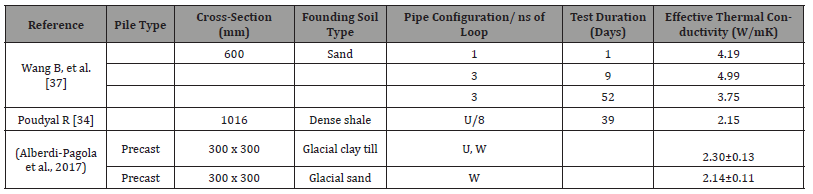

Table 3 presents a summary of thermal response tests conducted on different types of pile foundations having different cross-section pipe configurations, numbers of loops, and test duration.

Table 3:Summary of thermal response test.

Conclusion

This paper presents comprehensive literature on the significant amount of research undertaken on geothermal energy piles in the past years. This rapidly evolving and renewable source of energy is more environmentally friendly than conventional fuel sources and is considered to be largely untapped. This technology is however considered an expensive resource to tap into but with the utilization of foundations, the associated cost of drilling or construction is eliminated, and the foundation serves a dual purpose of structural stability and geothermal energy harvesting. Geothermal energy has been suggested to present the risk of triggering earthquakes in sites where they are been harvested. Thus, the potential effect of earthquakes and temperature have to be investigated.

Acknowledgement

None.

Conflict of Interest

There is no conflict of interest.

References

- Brandl H (2006) Energy foundations and other thermo-active ground structures. Géotechnique 56(2): 81-122.

- Jensen-Page L, Narsilio GA, Bidarmaghz A, Johnston IW (2018) Investigation of the effect of seasonal variation in ground temperature on thermal response tests. Renew Energy 125: 609-619.

- Jun Gao, Xu Zhang, Jun Liu, Kuishan Li, Jie Yang, et al. (2008) Numerical and experimental assessment of thermal performance of vertical energy piles: an application. Appl Energy 85(10): 901-910.

- Kwag BC, Krarti M (2013) Performance of Thermoactive Foundations for Commercial Buildings, in: Volume 10: Emerging Technologies and Topics; Public Policy. Presented at the ASME 2012 International Mechanical Engineering Congress and Exposition, American Society of Mechanical Engineers, Houston, Texas, USA, pp. 251-262.

- Martin JR, Abdelaziz SL, Olgun CG (2010) Renewable Energy Applications Using Thermo-Active Deep Foundations.

- Omer AM (2008) Ground-source heat pumps systems and applications. Renew. Sustain. Energy Rev 12(2): 344-371.

- Oravec J, Šikula O, Nováková I (2020) An Evaluation of the Mathematical Models of Energy Piles. Slovak J Civ Eng 28(1): 44-48.

- Makasis N, Narsilio GA (2020) Energy diaphragm wall thermal design: The effects of pipe configuration and spacing. Renew Energy 154: 476-487.

- Dickson MH, Fanelli M (2015) Geothermal energy: utilization and technology. Routledge.

- Tomlinson MJ, Woodward J (2007) Pile design and construction. Taylor Francis.

- Goldstein B, Hiriart G, Tester J, Gutierrez-Negrin L, Bertani R, et al. (2013) Geothermal energy, nature, use, and expectations, in: Renewable Energy Systems. Springer, pp. 772-782.

- Soltani M, Kashkooli FM, Dehghani-Sanij AR, Kazemi AR, Bordbar N, et al. (2019) A comprehensive study of geothermal heating and cooling systems. Sustain. Cities Soc 44: 793-818.

- GSHP (2012) Thermal pile design, installation & materials standards. Ground Source Heat Pump Association, Milton Keynes.

- Vasilescu AR (2019) Design and execution of energy piles: Validation by in-situ and laboratory experiments (PhD Thesis). École centrale de Nantes.

- ASHRAE I (2009) 2009 ASHRAE handbook: fundamentals. American Society of Heating, Refrigeration and Air-Conditioning Engineers.

- Manual J (2011) Residential Load Calculation. AC Contract. Am.

- IGSHPA (2009) Ground source heat pump residential and light commercial design and installation guide. Okla. State Univ.

- Knellwolf C, Peron H, Lalou, L (2011) Geotechnical analysis of heat exchanger piles. J. Geotech. Geoenvironmental Eng 137(10): 890-902.

- Seed HB, Reese LC (1955) The action of soft clay along friction piles. Am Soc Civ Eng Trans.

- Coyle HM, Reese LC (1966) Load transfer for axially loaded piles in clay. J Soil Mech Found Div 92(2): 1-26.

- Frank R, Zhao SR (1982) Estimation par les paramètres pressiométriques de l’enfoncement sous charge axiale de pieux forés dans des sols fins. BULL LIAISON LAB PONTS CHAUSS 119: 17-24.

- PJ Bourne-Webb, B Amatya, K Soga, T Amis, C Davidson, et al. (2009) Energy pile test at Lambeth College, London: geotechnical and thermodynamic aspects of pile response to heat cycles. Géotechnique 59(3): 237-248.

- Nusier O, Abu-Hamdeh N (2003) Laboratory techniques to evaluate thermal conductivity for some soils. Heat and Mass Transfer 39: 119-123.

- Hamdhan IN, Clarke BG (2010) Determination of thermal conductivity of coarse and fine sand soils, in: Proceedings of World Geothermal Congress, pp. 1-7.

- Luo J, Tuo J, Huang W, Zhu Y, Jiao Y, et al. (2018) Influence of groundwater levels on effective thermal conductivity of the ground and heat transfer rate of borehole heat exchangers. Appl Therm Eng 128: 508-516.

- Omer AM, Omer A (2014) Soil thermal properties and the effects of groundwater on closed loops. Int. J. Sustain. Energy Environ Res 3(1): 34-52.

- Vieira A, Maranha J, Christodoulides P, Alberdi Pagola M, Loveridge F, et al. (2017) Characterization of ground thermal and thermo-mechanical behaviour for shallow geothermal energy applications. Energies 10(12): 2044.

- ASTM D5334 (2014) D5334-14 Standard Test Method for Determination of Thermal Conductivity of Soil and Soft Rock by Thermal Needle Probe Procedure. ASTM Int. West Conshohocken PA USA.

- IEEE Std 442 (1981) IEEE Std 442-IEEE Guide for Soil Thermal Resistivity Measurements. EUA IEEE.

- Bose J, Smith M, Spitler J (2002) Advances in ground source heat pump systems-an international overview: Proceedings of the Seventh International Energy Agency Heat Pump Conference. Beijing, pp. 19-22.

- Salomone LA, Marlowe JI (1989) Soil and rock classification according to thermal conductivity: Design of ground-coupled heat pump systems. Electric Power Research Inst., Palo Alto, CA (USA); STS Consultants Ltd.

- Kluitenberg GJ (2002) 5.2 Heat Capacity and Specific Heat. Methods Soil Anal. Part 4 Phys. Methods 5: 1201-1208.

- Ali Moradi, KM Smits, Ning Lu, JS McCartney (2016) Heat transfer in unsaturated soil with application to borehole thermal energy storage. Vadose Zone J 15(10): 1-17.

- Poudyal R (2014) Thermal-mechanical Behavior of a Multiple-loop Geothermal Heat Exchanger Pile (PhD Thesis). Oklahoma State University.

- Howlader MK, Rashid MH, Mallick D, Haque T (2012) Effects of aggregate types on thermal properties of concrete. ARPN J Eng Appl Sci 7: 900-906.

- Loveridge F (2012) The thermal performance of foundation piles used as heat exchangers in ground energy systems (PhD Thesis). University of Southampton.

- Wang B, Bouazza A, Singh RM, Barry-Macaulay D, Haberfeld C, et al. (2013) Field investigation of a geothermal energy pile: initial observations, in: Proceedings of the 18th International Conference on Soil Mechanics and Geotechnical Engineering, Paris, France, pp. 2-6.

- Mimouni T, Laloui L (2014) Towards a secure basis for the design of geothermal piles. Acta Geotech 9: 355-366.

- Loria AFR, Bocco M, Garbellini C, Muttoni A, Laloui L et al. (2020) The role of thermal loads in the performance-based design of energy piles. Geomech. Energy Environ 21: 100153.

- Bao X, Li Y, Feng T, Cui H, Chen X, et al. (2020) Investigation on thermo-mechanical behavior of reinforced concrete energy pile with large cross-section in saturated sandy soil by model experiments. Undergr Space 5: 229-241.

- Eklöf C, Gehlin S (1996) TED-a mobile equipment for thermal response test: testing and evaluation.

- Mogensen P (1983) Fluid to duct wall heat transfer in duct system heat storages. Doc Swed Counc Build Res, pp. 652-657.

- Sanner B, Hellström G, Spitler J, Gehlin S (2005) Thermal response test-current status and world-wide application, in: Proceedings World Geothermal Congress. International Geothermal Association, pp. 24-29.

- Carslaw HS, Jaeger JC (1986) Conduction of heat in solids. Clarendon Press, Oxford, UK. Conduct. Heat Solids 2nd Ed Clarendon Press Oxf. UK.

- Eskilson P (1987) Thermal analysis of heat extraction boreholes.

- Beier RA, Smith MD (2002) Borehole thermal resistance from line-source model of in-situ tests. Ashrae Trans 108: 212.

- Jensen-Page L, Loveridge F, Narsilio GA (2019) Thermal Response Testing of Large Diameter Energy Piles. Energies 12(14):

- Beier RA, Smith, MD (2003) Minimum duration of in-situ tests on vertical boreholes. ASHRAE Trans 109: 475.

- Loveridge F, Low J, Powrie W (2017) Site investigation for energy geostructures. QJ Eng Geol Hydrogeol 50: 158-168.

- Badenes B, CD Santiago, Magraner T, Urchueguía JF, FPD Santayana, et al. (2017) Thermal characterization of a geothermal precast pile in Valencia (Spain), in: Proceedings of the European Geothermal Congress, pp. 10(9).

- Bouazza A, Wang B, Singh RM (2013) Soil effective thermal conductivity from energy pile thermal tests. Coupled Phenom Environ Geotech, Torino Italy, pp. 211-219.

-

Abdullah I Al-Mhaidib* and Kehinde Lemboye. A Review on Geothermal Energy Pile Foundation, Its Construction, Design and Thermal Testing. Glob J Eng Sci. 10(5): 2023. GJES.MS.ID.000747.

-

Conductivity, Energy pile, Geothermal, Heat transfer, Pump, Sustainable, Thermal

-

This work is licensed under a Creative Commons Attribution-NonCommercial 4.0 International License.